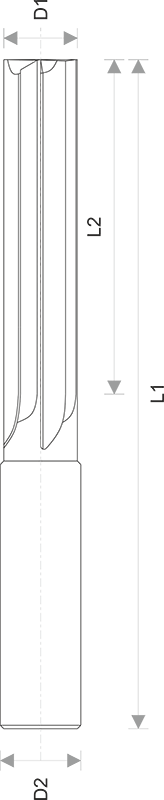

A Hole-mill is normally an undersized reamer with a boring geometry i.e. the size of the hole-mill is normally 0.2-0.6mm more than the size of the drill so that there are no drill marks on the hole plus the hole axis is corrected for subsequent reaming operation.

Generally used for axis correction before reaming as drilled holes are taper. holemill give corrct shapes to hole as need for reaming.

features

- Titanium 0.2-0.3 mm

- Steel & CI 0.3-0.4 mm

- Aluminium 0.5-0.6 mm

- Reliable

- Fine finish

Application

- Aerospace Industry

- Used in different industrial Application

- Hole mill give correct shapes to hole as need for reaming

- It is generally used for axis correction before reaming as drilled holes are taper